Acoustic Foam South Africa: A Comprehensive Guide

Article written by Brett Robinson the owner of Genesis Acoustics, 3rd April 2023

Fact checked by Steven Kartapanis, who studied acoustics at the Berklee College of Music

Table of Contents

Introduction

Introduction

1. What is Acoustic Foam?

Waffle profile studio foam - recording studio Cape Town

Contact us

Need help with your project? We're here to chat and get things moving in the right direction.

Customer Testimonial

"Genesis Acoustics recently performed outstanding work at our laboratory. They installed the waffle profile acoustic foam and industro-foam in our Clinical Pharmacology and Toxicology laboratories of the University of Cape Town.

This has helped to reduce the noisy sound generated by multiple Mass Spectrometer instruments and their roughing pumps by a significant amount.

Staff and students can now work on the LC-MS/MS instruments and spend extended periods of time in these labs without complaining of getting headaches from the excessive noise that those areas previously suffered from."

Willem Van Dalen

2. Can Any Foam be Called an Acoustic Foam?

Sound absorbing studio foam used together with QRD diffusers

Contact us

Need help with your project? We're here to chat and get things moving in the right direction.

3. How Does Acoustic Foam Work?

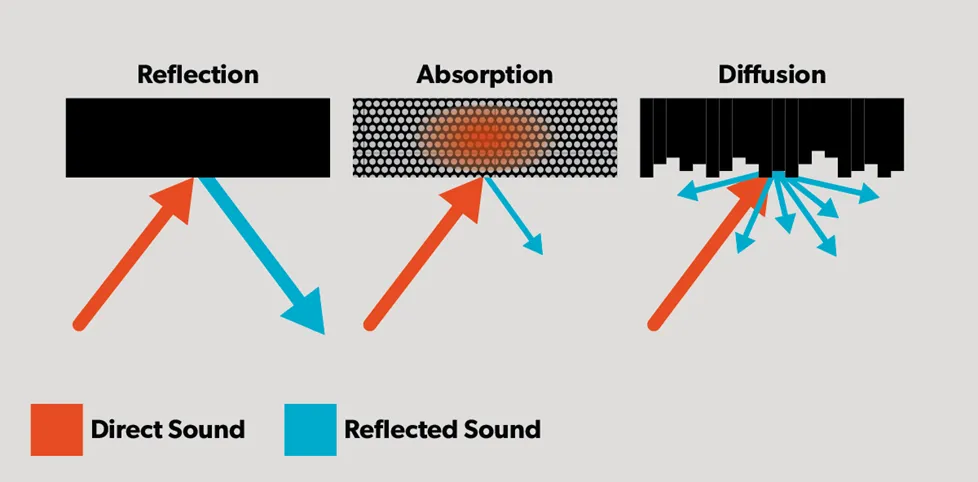

When sound strikes a surface such as a wall, 3 things happen

- Absorbed

- Passes through the structure

- Reflected back into the room

- Sound absorption

- Diffusion

- Soundproofing

- Room layout and design

Ideally, to save time and expense these factors should be considered in the planning stages, before the room or venue is built. However, we do a lot of retrofit acoustic treatment to help people and companies make the best of the facilities that they already have and overcome their noise problems.

Do you need help with your project? You can get in touch with us here.

Thickness

What is the Benefit of Absorbing Sound?

Uncontrolled Reverberation Degrades The Quality of The Audio Signal

What is Soundproofing Foam / Sound Proofing Foam?

Does the Profile of the Acoustic Foam Really Make a Difference?

Is Acoustic Foam All That I Need to Treat My Room?

Contact us

Need help with your project? We're here to chat and get things moving in the right direction.

How to Judge the Credibility of a Company Offering

Soundproofing and Acoustic Products

This short article could save you a lot of pain and frustration.

Make sure you're dealing with someone legit.

What Types of Acoustic Foam are Available?

4 Types of Open Cell Foam Used for Acoustic Applications

1. Flammable Polyurethane Foam

2. Flame Retardant Polyurethane Foam

3. Carbon Impregnated Class 0 Polyurethane Foam

4. Melamine Foam

Perforated Polyethylene Closed Cell Foam

Contact us

Need help with your project? We're here to chat and get things moving in the right direction.

Open Cell Foam vs Closed Cell Foam

Understand Which Product to Use Where & Why

Open Cell Foam

- Tiles - Square

- Panels - Rectangular

- Especially cut shapes for decorative acoustic applications e.g. circles, triangles etc.

- Rectangular hanging baffles

- Square or rectangular acoustic clouds

- Round cylindrical hanging baffles

1. Sound Absorption

2. Sound Attenuation

3. Vibration Damping

Closed Cell Foam

1. Sealing Air Gaps

2. To Damp Vibration

3. As an Acoustic Underlay

4. To Decouple Structural Building Components

5. Under the Legs of Chairs & Tables

Contact us

Need help with your project? We're here to chat and get things moving in the right direction.

What is the Best Soundproof Foam?

8 Questions to Help You Select the Right Type of Acoustic Foam for the Job

- Where are you going to use the foam? What is the application?

- Is the look of the foam important or is it only important that it meets the technical criteria?

- Is a flame retardant foam good enough or do you need a Class 0 non-combustible foam?

- Will the foam get exposed to direct heat and if so, to what max temperature & for what duration of time?

- Will the foam ever get exposed to high humidity, get wet from rain or need to be washed down? If yes, look here

- What type of sound or noise are you trying to treat? e.g. vocals, music, machine noise, generator etc.

- What level of sound absorption do you need?

- What is the typical sound level output of the source noise in 1/3 octave frequency bands? This can be determined by an instrument that measures the RTA (real time analysis) of the noise source. You can book a site inspection here and we'll do this for you.

There is No One Size Fits All

- Formulation: Learn more

- Cell structure: Open or closed cell

- Flammability

- Density

- Thickness

- Profile

- Colour

Contact us

Need help with your project? We're here to chat and get things moving in the right direction.

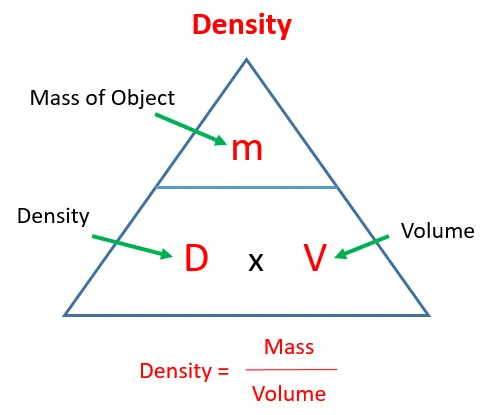

What Density Acoustic Foam Should You Use & Why?

I have worked with bonafide acoustic foam with a density from as low as 10kg/m3 and as high as 90kg/m3 for diverse applications.

The Type of Application Will Determine the Value of the Density:

1. Sound Absorption

2. Sound Attenuation

Top Tips to Remember Regarding Density

1. Don't get Distracted

2. What is the Application / Where will the Foam be Installed?

- Inside a generator housing: High density, non-flammable Class 0 Genesis Foam. Why? Because the high density will assist with sound attenuation and the damping of structural vibration.

- On the walls of a studio / band practice room: Low to medium density foam such as waffle profile acoustic foam

- Under a flush, skimmed ceiling in a room: Low density product such as Industro-Foam

- Suspended Rectangular Baffles: Low density product such as Industro-Foam

- Suspended Cylindrical Baffles: Low density product such as Industro-Foam

- Suspended Acoustic Clouds: Low density product such as Industro-Foam

Contact us

Need help with your project? We're here to chat and get things moving in the right direction.

Can Acoustic Foam be

Used for Noise Cancellation?

Two Types of Passive Noise Cancellation

1. Seals

2. Sound Absorption

The Difference Between Sound Absorption & Sound Attenuation

Contact us

Need help with your project? We're here to chat and get things moving in the right direction.

5 Factors That Will Influence

Which Acoustic Foam You Buy

1. Your Budget

- Buy less but of a better quality, credible product and add on as you can afford to.

- Don't succumb to temptation and buy a cheap product, that has no credibility and will almost certainly not do what you need it to do anyway. There's nothing worse than buyers remorse. Just remember if it's waaaaay cheaper, there's reason and it's probably not because you just stumbled across the deal of the century.

2. Cost of Shipping, Handling, Duties & VAT

3. Local Availability and Support

4. Performance

5. The Credibility of the Supplier

Contact us

Need help with your project? We're here to chat and get things moving in the right direction.

6 Reasons Why Acoustic Foam is Popular

1. It's Top of Mind

2. For It's Cool Appearance

3. It's Lightweight and Easy to Install

Convenience

- It's lightweight and therefore easy to ship or pick up at a shop.

- It's also easy to install

- Doesn't require the drilling of any holes. Just apply some adhesive to the back of the tiles and press them to the wall in the desired position.

4. It's Easy on Hands, Eyes and Doesn't Cause Dust

5. It's Cheap

What is the actual quality of the product you are looking at? Remember - it's easy to make and sell a cheap product and make bold claims but it's far more difficult to properly develop a product, get it independently acoustically certified and employer trained, experienced staff - this process costs an investment in time & money but results in a quality product and service.

6. People Don't Know What Else is Available

Contact us

Need help with your project? We're here to chat and get things moving in the right direction.

7 Jobs That you Should NOT Use Acoustic Foam For

Whatever You Do - Avoid the Last 2

1. Diffusers / Diffusion and Open Cell Foams

2. Where a Non-Flammable Acoustic Insulation is Required

3. Inside a Drywall, Above a Ceiling or Under a Floor

4. To Soundproof a Door

5. To Soundproof a Generator

- You can void the warranty on your generator

- Cause it to overheat

- Last, but not least - using the wrong materials can cause a fire.

Don't worry, we have the experience and expertise to help you get the job done right - so that running your generator doesn't disturb your own household and so you can remain on friendly terms with your neighbours.

The soundproofing of generators is a big topic, but to make it easy I've written a useful article with my top tips and solutions. To find out more about the soundproofing of generators, please check it out the article here.

6. To Soundproof Your Mother in Law

- Set ground rules for noise levels and stick to them religiously. This will help keep everyone calm and relaxed.

- Try not to engage in any conversations that are too noisy - this includes TVs, radios, etc.

- Find a quiet corner or room within the home where you all can meet without disturbing each other unnecessarily.

- Have family meetings at an early time in the day when there isn't much activity going on.

- Avoid playing noisy, outdoor activities - inside your home.

7. To Soundproof Your Children

Contact us

Need help with your project? We're here to chat and get things moving in the right direction.

Acoustic Foam is Ideal For Jobs Like These

1. Voice Overs

2. Recording Studios

Studio Foam

3. Band Practice Rooms

- At volume levels of between 100 - 105dBA it's possible to damage your hearing within 15 minutes.

- Between 105 - 110dBA you can damage your hearing within 5 minutes.

These are scary figures because it can happen so easily. The problem with hearing loss is that it's permanent, so that means we all really need to look after our hearing.

4. Drum Practice Room

5. Home Cinema Rooms

6. Shooting Ranges

7. Gaming Room

8. Home Entertainment Areas

9. Soundproofing of Noisy Generators

Contact us

Need help with your project? We're here to chat and get things moving in the right direction.

Foams to Avoid for Soundproofing & Sound Absorption

1. Bass Traps

2. Expanding Foam

3. Foam Without Legit Credentials

4. Fire Safety

Acoustic Foam South Africa

- Flame retardant Waffle Profile Acoustic Foam

- Non-combustible Genesis Class 0 Acoustic Foam

Contact us

Need help with your project? We're here to chat and get things moving in the right direction.

People Also Ask

Is acoustic foam the same as soundproof foam?

This is fundamentally the wrong question to be asking. Acoustic foam is designed to absorb sound waves and reduce echoes within a room, while soundproofing is designed to block sound from entering or leaving a room. Acoustic foam is often used in recording studios, home theaters, and other environments where sound quality is important, to control and diminish unwanted reflections. Sound absorption is applied inside a room as a finishing, whereas the methods of soundproofing are different because they are structural.

What is the best thickness for acoustic foam?

The best thickness for acoustic foam depends on the specific needs of your space and the level of sound absorption required. Generally, thicker foam will absorb more sound over a broader frequency range than thinner foam, but there are other factors to consider such as the density, formulation and profile of the foam. It's important to consult with an acoustic professional to get the right advice on the best thickness of foam for your specific needs.

Brett Robinson Bio

Brett Robinson is a well-known figure in South Africa, in the field of acoustics and soundproofing, with a career spanning over two decades. As an entrepreneur, blogger, public speaker, husband, and father of three, Brett has balanced his professional pursuits with a rich personal life. He founded and has been managing Genesis Acoustics since 1997, leading the company in designing and manufacturing innovative acoustic solutions such as soundproof doors, generator enclosures, and various sound-absorbing room finishes.

His expertise and commitment to quality have earned him the trust of some of South Africa's biggest companies, including Barloworld, Mercedes Benz East London Plant, Durr, Ford Motor Company South Africa, Volkswagen South Africa, Nissan, 3M, Coca Cola Bottling Plant Port Elizabeth, banks, Starbucks, Mugg & Bean and many more. His impact extends beyond large corporations to churches, recording studios, and numerous small to medium-sized businesses.

Brett leads a dedicated team of over a dozen full-time staff, with Genesis Acoustics represented in various major centres across South Africa. His contributions to the industry have not only shaped the soundscapes of countless architectual spaces but have also set a high standard for acoustic and soundproofing solutions nationwide.

When not working in one of his companies, Brett enjoys spending time with his family, writing, mountain biking, and training in Krav Maga. His diverse interests and commitments reflect his dynamic approach to life and work, embodying a holistic vision of success that values both professional achievement and personal fulfilment.

Links

Links

https://www.instagram.com/genesis_acoustics

https://www.facebook.com/GenesisAcousticsRSA

https://www.soundproofmygenerator.co.za/

https://what3words.com/definite.major.bubbles

The National Institute of Building Sciences - Acoustics: https://www.nibs.org/page/acoustics

The Glass Association of North America (GANA): https://www.glasswebsite.com/

The International Noise Control Engineering (INCE-USA): https://www.inceusa.org/

Sound and Vibration Magazine: https://www.sandv.com/

U.S. Green Building Council (USGBC) - LEED Rating System: https://www.usgbc.org/leed